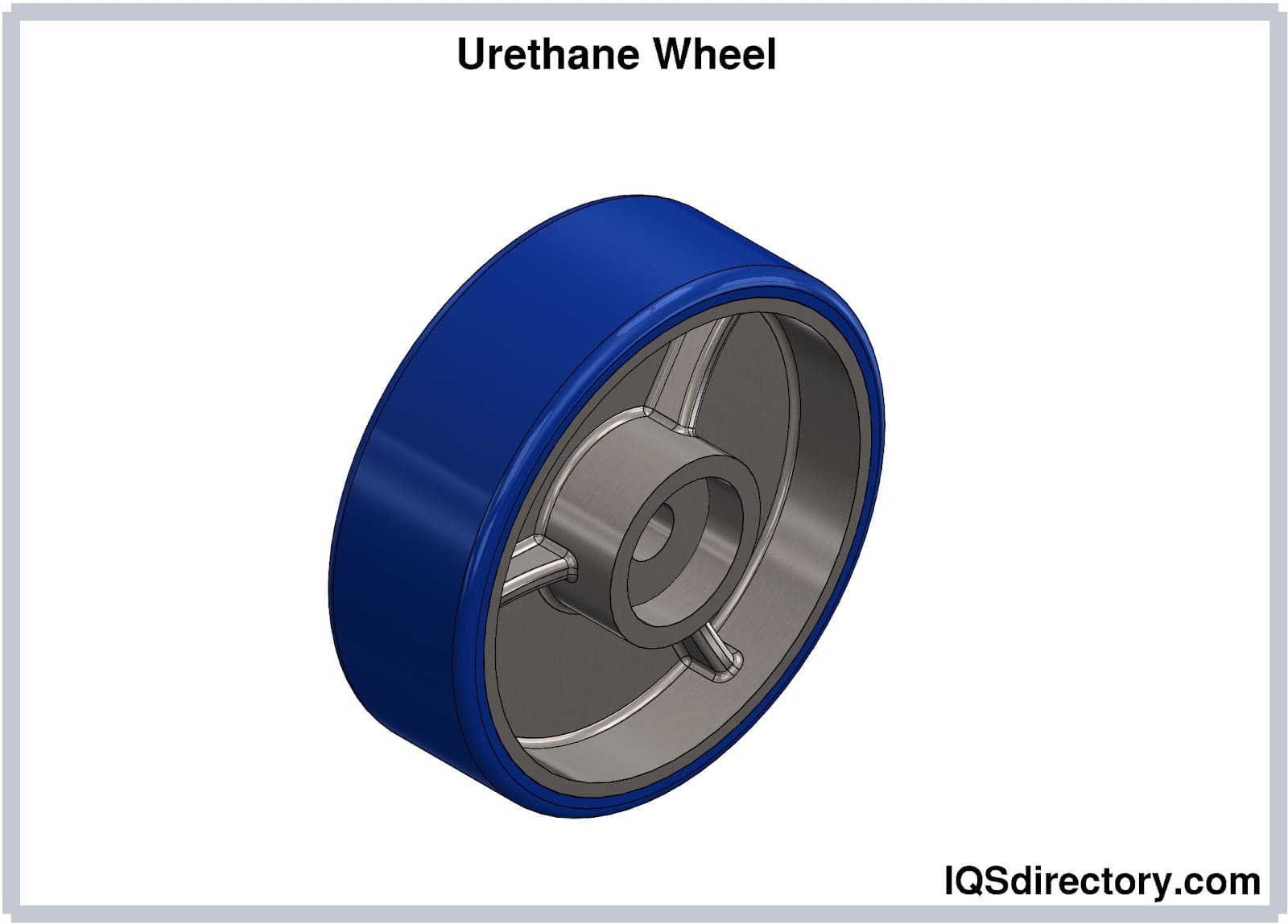

Polyurethane casters are undriven wheels made from polyurethane, designed for attachment to the bottom of large objects to enable movement. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

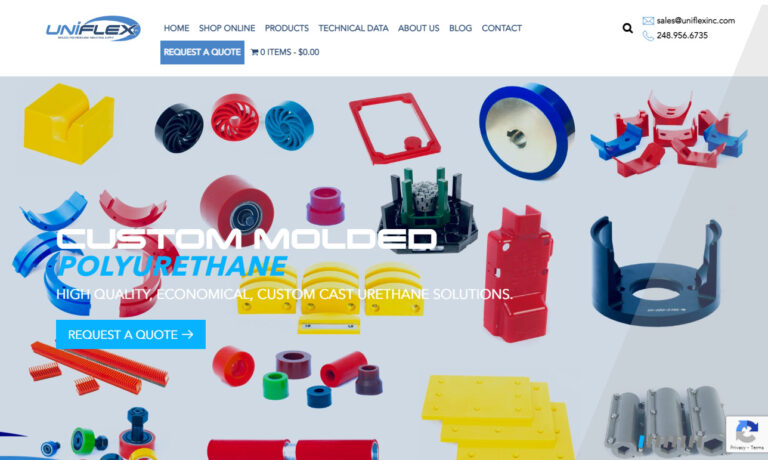

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

More Polyurethane Caster Companies

What are Polyurethane Casters?

Polyurethane casters are undriven wheels made from polyurethane, designed for attachment to the bottom of large objects to enable movement.

How Polyurethane Casters Are Made

The process of making polyurethane casters involves:

Open Molding

In this technique, the two-part polyurethane is mixed to produce a uniform mixture. The mixture will then be de-gassed and poured into an open mold. The setting of the mixture occurs quickly, so it is important that the process is conducted as quickly as possible and the material is mixed in small batches to avoid wastage.

Machine Casting

This process is almost similar to the process of open molding. However, the entire process is conducted in a casting machine. This will save a lot of time and provide a more consistent final product.

Spraying and Coating

This process is a simple one. The polyurethane is sprayed onto a component so that a coating of polyurethane is provided.

Injection Molding

This process is generally used for thermoplastic materials. Polyurethane pellets are fed into a reciprocating injection molding machine and melted by the heated reciprocating screw.

At the same time, the liquid material is fed through the machine and injected into a mold. The material is allowed to cool down and then removed from the mold.

Machining

The machining of most grades of polyurethane can be done using conventional methods like turning, grinding, milling and drilling. However, for softer materials, special techniques are required. One technique that can be used for softer materials is freezing the material before machining so its hardness can be increased.

Machining to relatively high tolerances is possible when using hard polyurethane. The material can be improved further by using the grinding process.

Types of Polyurethane Casters

The different types of polyurethane casters include:

Medium Duty Polyurethane Caster

These types of casters cost less. They consist of a highly resistant steel bracket that is pressed. They are non-marking, and they exhibit good abrasion resistance. In addition, they have good dampening with a low resistance to rolling.

They are capable of carrying high loads, especially at low speeds. They are resistant to multiple diluted acids, oils, greases, and alkalis.

Medium Duty Polyurethane on Polypropylene Caster

These consist of a double ball bearing. They offer non-marking tread and excellent resistance to abrasion. They also offer excellent resistance to impact and exhibit high resistance to greases and oils.

Medium Duty Polyurethane on Aluminum Caster

These have a robust center of aluminum bonded with a tread of cast polyurethane. They are non-marking, and they exhibit properties of abrasion and impact resistance.

Heavy Duty Polyurethane Caster with Cast Iron Center

These have a strong center made from cast iron and are bonded with a high-grade polyurethane tread; they also consist of strong pressed steel brackets with a chromate and zinc finish. They offer a non-marking tread and excellent abrasion and impact resistance. They are also resistant to greases and oils.

Applications and Benefits of Polyurethane Casters

The applications and benefits of polyurethane casters include:

Applications of Polyurethane Casters

- Overhead Conveyor Systems

- Industrial Carts

- Railroad

- Industrial Washer Systems

- Roll forming Machinery

- Elevators

- Hyperloop

Benefits of Polyurethane Casters

The benefits of polyurethane casters include:

Noise Reduction

Polyurethane casters are used in a variety of industries to reduce noise levels. Polyurethane casters are considerably quieter compared to cast iron or steel. The polyurethane acts like a shock absorber on a terrain that is uneven.

Dynamic Load Bearing Capability

Compared to rubber casters, polyurethane casters offer a higher load-bearing capacity. They also offer good compressive deformation behavior.

Floor Protection

Polyurethane casters function efficiently and are generally non-marking. They function well on hard surfaces such as concrete, even hardwood, and ceramic tiles. They reduce direct stress on a floor because of their large surface area and shock absorption.

High Grip and Traction

Polyurethane casters provide less resistance than others, making them some of the most ergonomic on the market. In addition, polyurethane casters have properties that allow for improved grip and traction compared to other hard wheels. They also reduce the quantity of load on the wheel for the achievement of the desired driving force.

Resistance to Corrosion

Polyurethane wheels are resistant to corrosion and a multitude of chemicals like greases, oils, and cleaning agents found in industrial and commercial environments.

Choosing the Right Polyurethane Caster Manufacturer

To make sure you have the most productive outcome when purchasing polyurethane casters from a polyurethane caster manufacturer, it is important to compare at least 4 to 5 companies using our list of polyurethane caster companies. Each polyurethane caster manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each polyurethane caster company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple polyurethane caster companies with the same quote.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services