Urethane manufacturing uses urethane to fabricate and produce a variety of products using molds and other methods. Raw urethane can come in several forms, which include low density flexible or rigid foam, soft solid elastomer, or hard solid plastics. The flexibility, adaptability, and mechanical properties of urethane offers various advantages that are not available in other industries such as the production of rubber. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

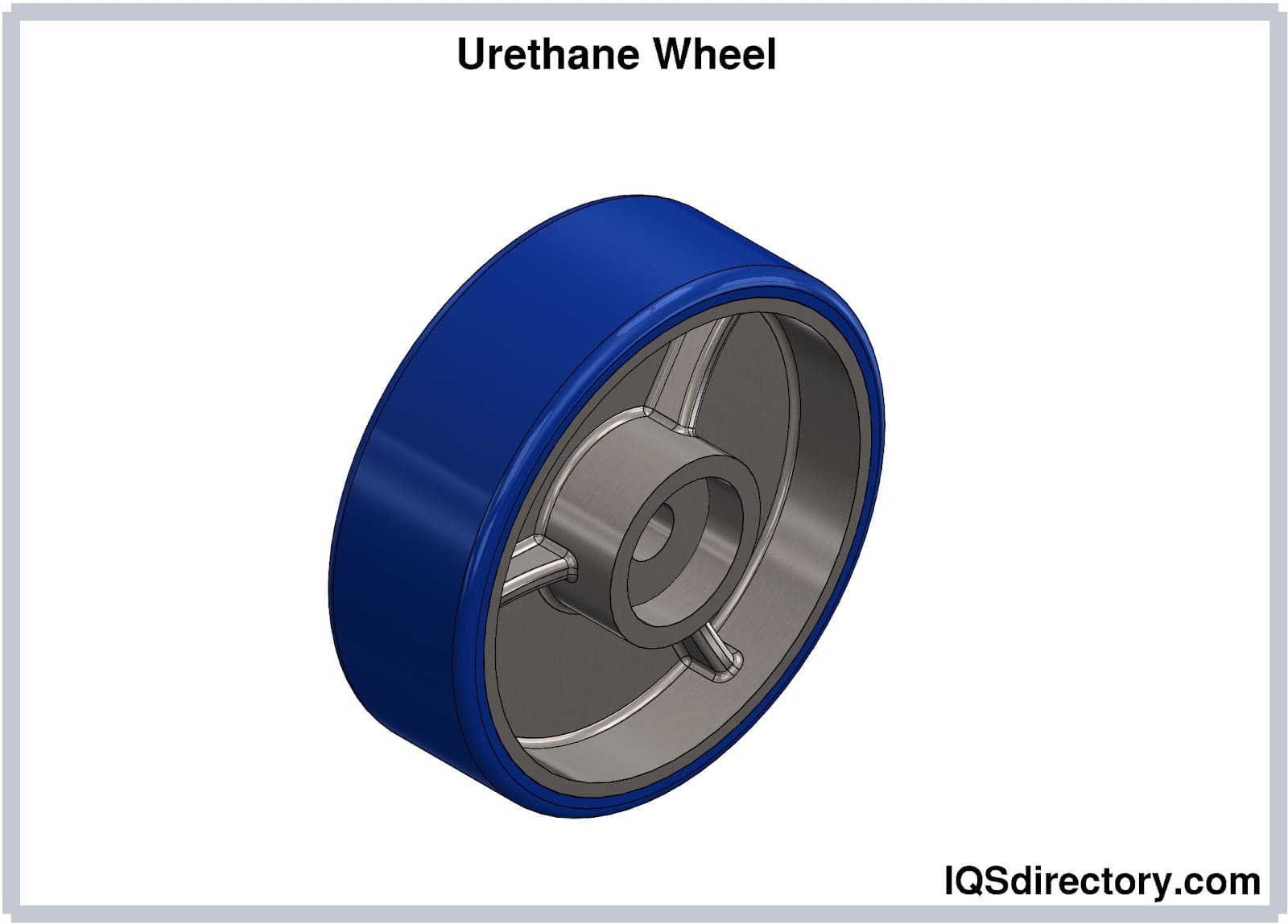

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

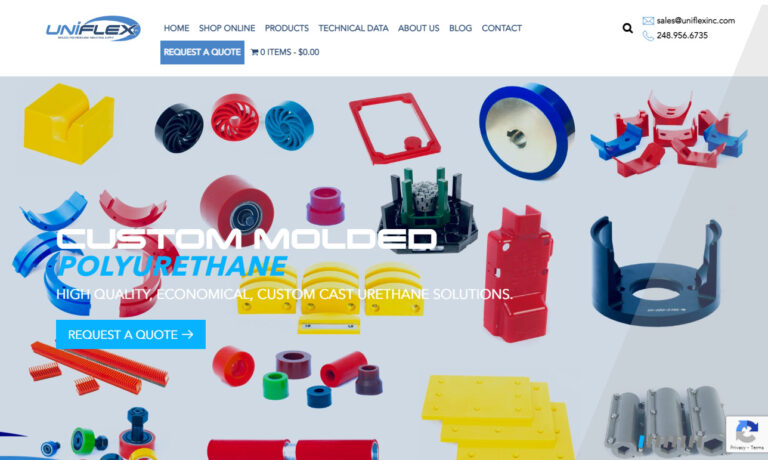

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

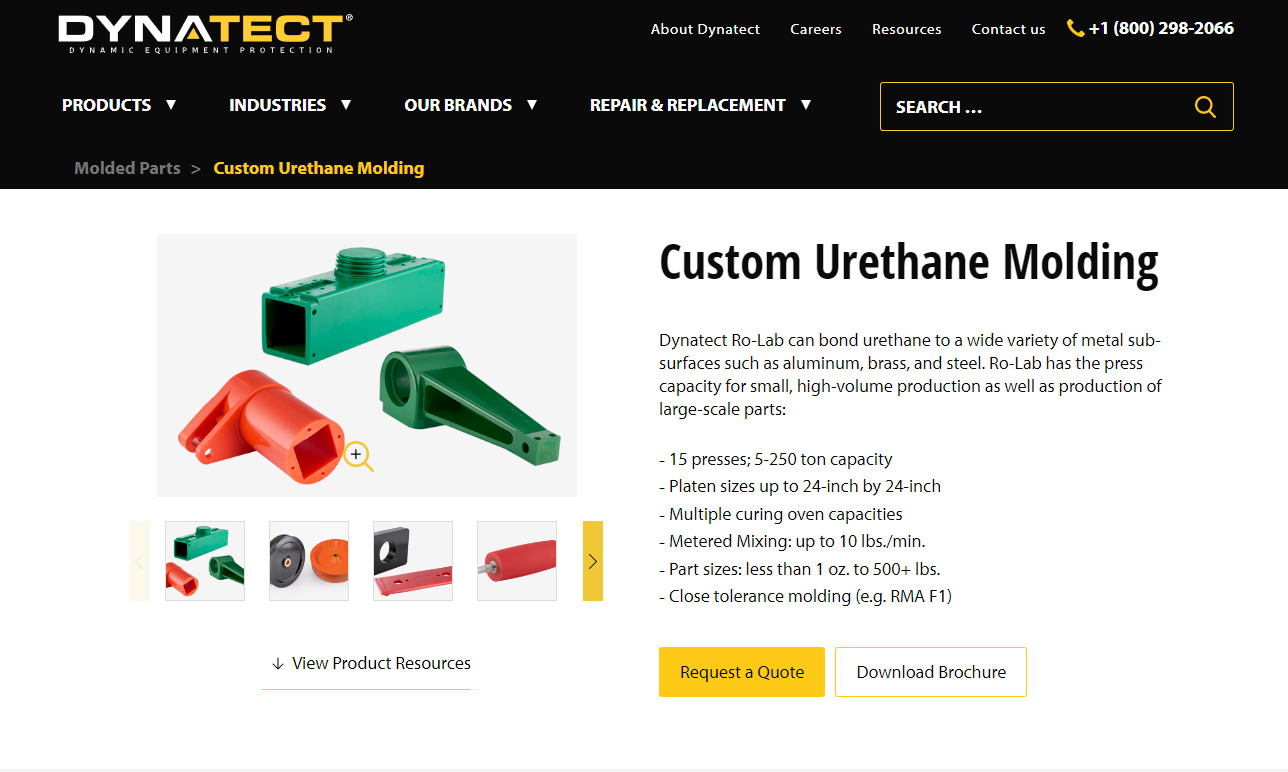

At Dynatect Ro-Lab, Inc., we take pride in our expertise and specialization in polyurethane molding, offering unparalleled solutions for a myriad of applications. With our advanced capabilities, we excel in bonding urethane to diverse metal sub-surfaces, including aluminum, brass, and steel. As a team, we understand the unique demands of various industries, and our commitment to quality is...

More Urethane Companies

Things That Urethane Manufacturers Stress

One of the things that urethane manufacturers stress are the many benefits that come from using urethane produced products. Some of the notable qualities of urethane are its abrasion, cut, tear, oil, ozone, and radiation resistance. It has load bearing ability, a wider range of densities, and is colorable.

What is Urethane Manufacturing?

One of the major discoveries that has led to the success of urethane manufacturers is that urethane has the strength, density, and durability to replace rubber in several applications. Urethane, or polyurethane, is formed from a complex set of chemical processes. The formation of urethane involves the reaction of a polyol with a diisocyanate or polymeric isocyanate in the presence of a catalyst.

The type and qualities of the final material formed from the process depends on the types of diisocyanates and which of the wide range of polyols is chosen. These choices lead to foams, coatings, adhesives, sealants, and elastomers that can be used to create a wide variety of products. The careful handling and blending of the various chemicals are carefully controlled to ensure the quality of the final polyurethane.

Urethane Manufacturing Processes

Once urethane manufacturers have created the raw material, they can choose how to shape and form it into the vast and wide range of products that are used for commercial and industrial applications. One of the widely used processes performed by urethane manufacturers is urethane casting, which can be open or closed.

Polyurethane that has been molded has the combined properties and characteristics of plastic and rubber. It is for this reason that urethane manufacturers’ products are sought after as solutions for the production of durable, long lasting, and strong assemblies and designs. What makes urethane cast parts a primary source of product production is its low cost and flexibility since it can be shaped and formed into any number of desired forms.

The methods of urethane casting used by urethane manufacturers is a process that can produce short, small runs of limited quantities or larger runs with higher volume. Products produced by urethane casting have exceptional finishes that do not require post process cleaning, smoothing, or polishing.

The casting process involves getting a pattern, creating a negative mold from silicone, and filling the mold with urethane. Once the urethane has cured, the cast part is removed. This process is repeated several times to produce multiple parts.

In the closed mold process, or injection molding, the liquified urethane is injected into the mold cavity at high pressure so as to fill the mold. The injection process has a fast cycle time and can be completed in a matter of seconds. The speed of the process is facilitated by cooling lines that reduce the time it takes for the liquid material to solidify.

The Benefits of Using Urethane

Urethane manufacturers realize that urethane parts are an essential component of many of the items we use. They use polymers that have a strong yield and exceptional stability. The manufacturing of urethane parts has been analyzed, developed, and perfected to be one of the most efficient methods for producing high quality components.

The main benefit of urethane fabricated parts is their low cost compared to ones made from rubber or metal. An added value for urethane parts is their recyclability when they are no longer needed or wear out. The previously shaped material can be repurposed and returned for reassembly and manufacturing.

The need and use of urethane components and parts is ever growing as more and more industries are finding the value of urethane as well as its abilities and strength. From aerospace and automotive production to medical applications and household items, urethane is the most relied on material that has the characteristics and qualities to provide continual top performance.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services