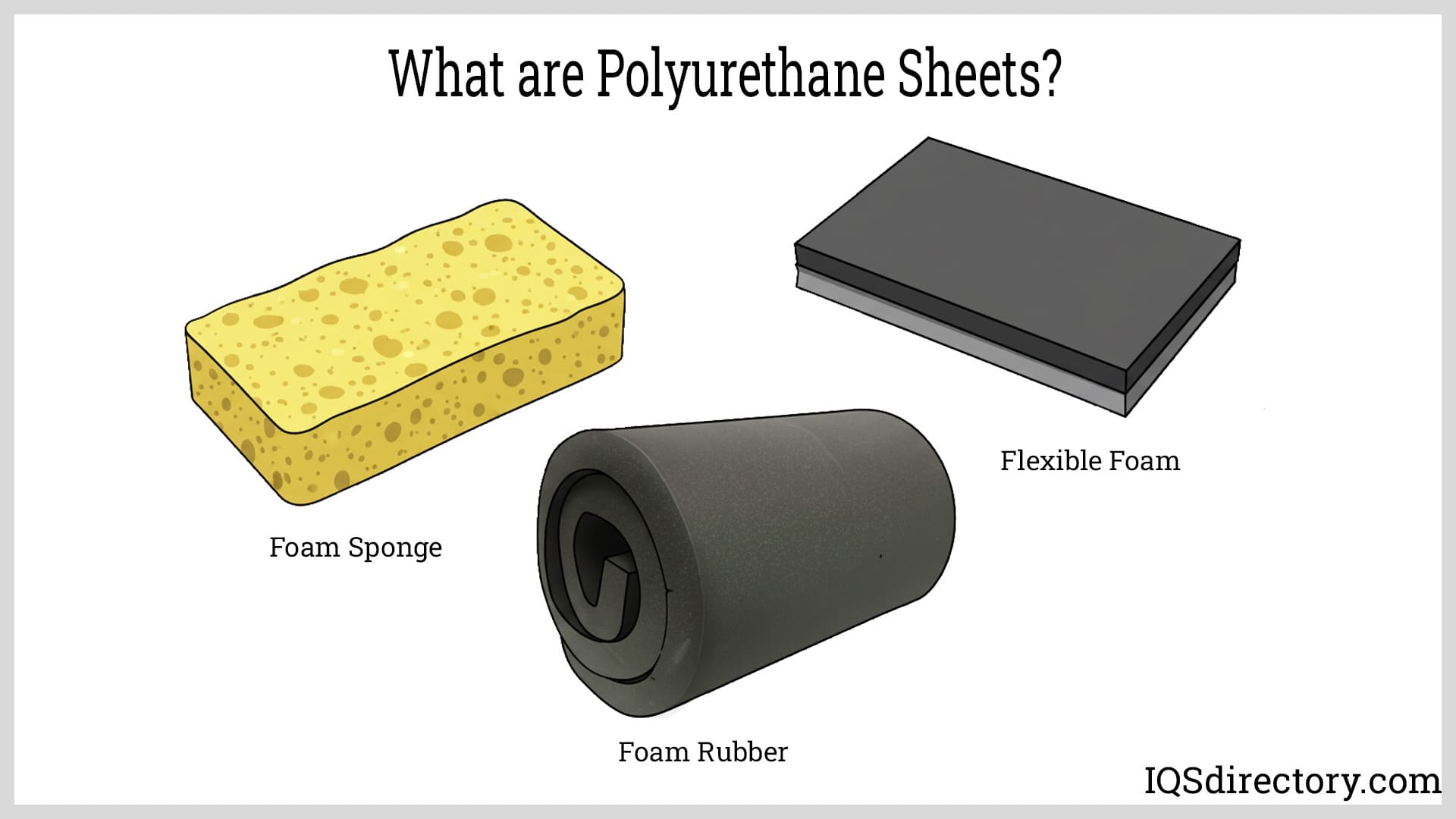

Urethane is a high-performing industrial substance with exceptional mechanical and physical properties that other materials can’t match. Urethane can resist ripping, cutting, and abrasion and has exceptional flexibility. In addition, urethanes occur in various densities and durometers (degrees of hardness). As a result, the finished urethane components might range in hardness from a bowling ball to gum. Read More…

TPC, Inc. is a leader in the polyurethane molding industry. Our state-of-the-art manufacturing facilities focus on providing high-quality products, competitive pricing, and exceptional customer service. Our team of experts is dedicated to the production and innovation of our products. As a result, TPC, Inc.’s custom-fit solutions are perfected for customers of all industries.

From concept, to production, to delivery, we have over 40 years experience with made-to-order cast urethane & cast polyurethane elastomer products. Weaver Industries offers urethane wheels, polyurethane molding, molded urethane, urethane sheets, & urethane/polyurethane manufacturing. Skilled at custom casting, discover the advantages of our urethane sheet and Action Mallet heads.

FallLine has been a manufacturer of custom polyurethane molding products for various industries since 1981. We offer a wide range of proven materials ranging from 40A - 80D, as well as the capability to formulate materials to meet specific needs.

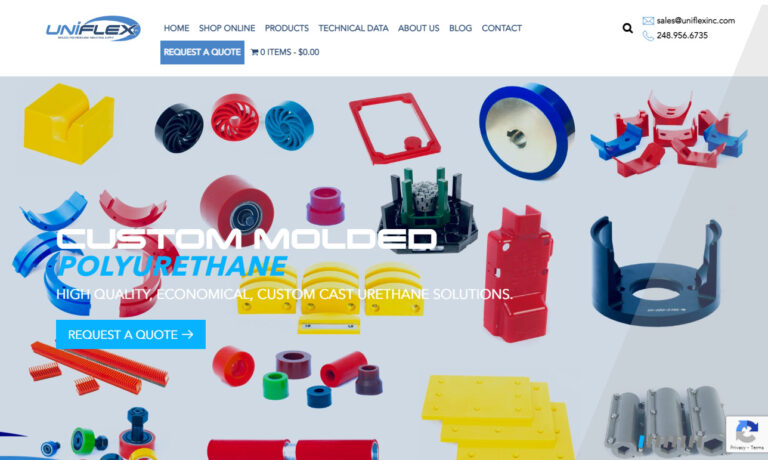

Since 1979, Uniflex has been a leading manufacturer of urethane products. We provide high-quality urethane rollers and urethane castings, as well as urethane molded products available in an array of colors. Uniflex offers customized body blocks and engine components for the automotive industry. Our team is dedicated to advancing our company and raising industry standards.

More Urethane Sheet Companies

Considerations When Buying Urethane Sheets

Before purchasing urethane sheets, talk with a urethane company. When contacting urethane producers, the following details should be mentioned to receive the proper urethane sheets:

- Determine the environment the urethane sheet will be in. Although it is straightforward advice, many consumers overlook environmental factors like wetness and humidity. The customer should disclose these factors because they can significantly impact the urethane sheeting required.

- Determine the function of the urethane sheets. Knowing the function of the sheets beforehand helps direct the process. In addition, the customer should state whether the urethane sheets will be subjected to high temperatures.

Personalized Urethane Sheets

Typically, suppliers' inventories of popular sheet sizes are sufficient, but certain customers demand specially molded sheets. A purchaser’s required composition, size, and color should be offered upon request. Regarding the hardness range, the company will determine the standard. However, observing a range of 45 Shore "A" durometer to 60 Shore durometer is typical.

How to Choose a Urethane Supplier

Deciding between urethane manufacturers is equally important to production preparation. Some pointers on how to select the best choice are below:

- Experience and Innovation: It’s good to look for an experienced manufacturer who has served a wide range of clientele from various industries. The company should focus on innovating and establishing industry standards while creating cutting-edge processing techniques and novel formulations.

- Quality Control: The urethane manufacturer should adhere to a strong pledge to produce top-notch goods exclusively. Quality begins when a manufacturer listens to customers about their unique requirements.

Urethane Component Advantages

Urethane sheets are primarily used to lessen wear from abrasive materials. In addition, different backing supports and wear characteristics are available for the sheets. These sheets, often referred to as urethane film, are excellent for making affordable parts with predetermined thicknesses instead of conventional molding techniques. One urethane sheet can produce nearly a thousand pieces in many applications, making it a useful material for producing replacement OEM parts of higher quality.

For many industrial applications, urethane components, including urethane sheets, have long been the ideal option. However, as previously indicated, the material offers physical and mechanical characteristics that are difficult to compare. In actuality, urethane can be developed to become more powerful, lighter, quieter, quicker, and less expensive than other materials.

Its greatest strength is the ability to be made more flexible and resistant to cutting, abrasion, and wear using different formulations. There are many other characteristics and features of urethane components. However, some are particularly advantageous for industrial applications. The advantages and applications listed below support the material's significance:

Versatility

One of the most flexible polymers on the market, urethane may be modified to match virtually any application. As a result, products of practically any size and hardness can be easily produced by adjusting molds and formulas.

Extended Product Life

Urethane sheets are promised to endure longer than conventional rubber sheets. This long life is because rubber degrades slowly, whereas polyurethane does not and has a substantially stronger tear, abrasion, thermal aging, and impact resistance.

Adaptive Sizes

The size of the sheets can be changed instantly. The length, width, and thickness can be changed with moveable urethane sheet molds without making new tooling. When bespoke sizes are required, this helps the customer save time and money.

Resistance to Ozone

Because urethane sheets can withstand ozone, they are suitable for long-term uses. In experiments when ozone concentrations exceeded 1,000 PPM, polyurethane still performed well, showing that it can withstand the negative effects of ozone. Ozone is a powerful oxidant, which can harm materials after a certain amount of time.

There will be apparent fissures in softer materials, like rubber, whereas in harder materials, like metals, there will be progressive oxidation. Contrarily, polyurethane can survive the impacts of ozone, making it the perfect material to use—especially because it may be exposed to air and other environmental factors directly. This resistance is why urethane is employed, among other things, to create weatherproof seals, coatings, and gaskets.

Anti-Corrosion

Chemical exposure is frequently unavoidable. In this situation, a material that can withstand chemical corrosion is required. The variety of urethane formulas available enables this material's resistance to various chemicals. Slush pumps, employed in petroleum engineering, are one application that calls for this feature. For example, take a pump which circulates drilling fluid; it must be chemically resistant to prevent corrosion. In addition, the metal structure inside the slush pump's propeller can be shielded by a polyurethane coating applied to the propeller. As a result, the pump's lifespan is increased while the need for replacement or repair is reduced.

Infection Resistance

The product has outstanding resistance to mold, mildew, and fungi. The spaces between surfaces are filled with a foamy liquid known as caulk, one of the urethane formulations. For instance, caulking is required to seal walls and various seams in damp settings like swimming pools and bathrooms to stop the formation of mold, mildew, and fungi between the areas. The bathrooms in the house are simple to clean because of the usage of this urethane component. Additionally, urethane is necessary for the prevention of mold and other hazards for toilets and swimming pools.

Additional Applications

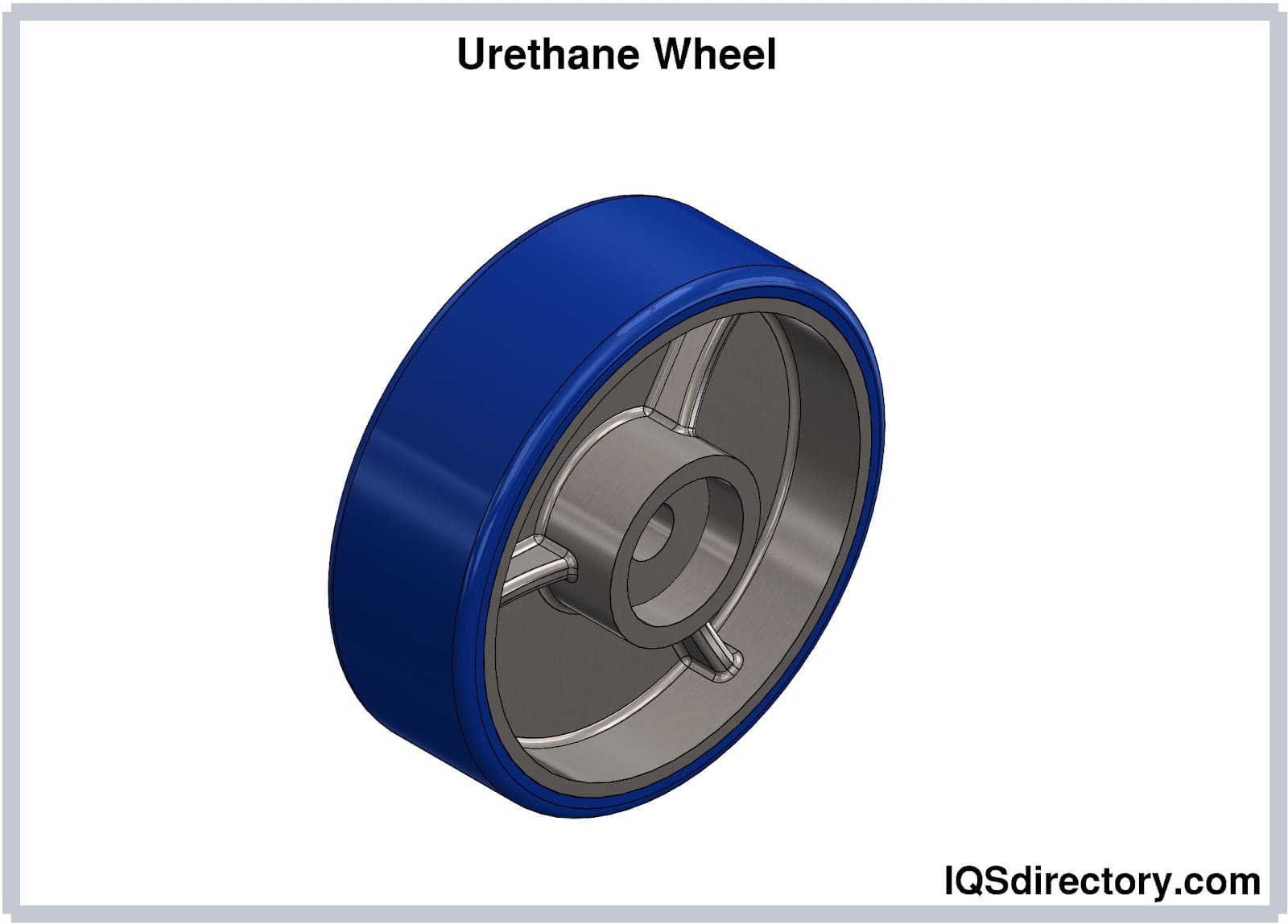

The material can be employed in various applications thanks to several urethane formulas. There are benefits that one might need to be made aware of. For instance, urethane can outlast metals and plastics due to its abrasion resistance. It is perfect for use in machine mounts and wheels because of this.

A urethane sheet is perfect for cable harnesses and molded wire, which are used in electrical assemblies since urethane also has excellent electrical insulating properties. Components of urethane, like urethane sheeting, may be used in various applications. Understandably, this discovery has several applications across various industries, given its different formulations.

Choosing the Right Urethane Sheets Supplier

To make sure you have the most beneficial outcome when purchasing urethane sheets from a urethane sheet supplier, it is important to compare at least 5 suppliers using our list of urethane sheet companies. Each urethane sheet supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each urethane sheet company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple urethane sheet companies with the same message.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services